Description

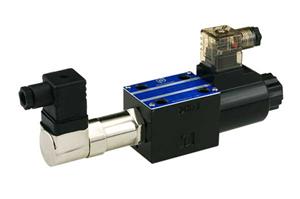

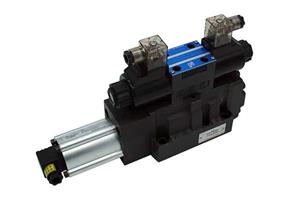

A safety valve is composed of a directional valve and an electric position detector. It is mainly developed for the plastic machinery and casting machinery industry. The built-in position sensor contact in the pressure safety valve can conveniently and accurately detect the spool position.

The detection signal will be entered into the industrial computer for operation, and the operation result can be used to control and drive the other hydraulic components or mechanisms.

Its role is to ensure normal operation of equipment only when the safety door is shut, so as to prevent personal injury and equipment damage caused by improper operation or when the door is unclosed.

Types of Safety Valve

1. LSV Safety Valve

2. SWHPS Solenoid Directional Safety Valve

3. SWPS Hydraulic Operated Directional Safety Valve

4. DCPS Mechanically Operated Directional Safety Valve

Advantages of Two Way Cartridge Valve

1. By CE certified

2. Inductive sensor assures high accuracy and repeatability of detection position

3. Non-contact typed structure contributes to longer service life and fast response

Notes of Safety Valve

1. When the sensor is used in inductive load, such as electric motor, relay coil, etc., the contact will be added with a high induced voltage when the (load circuit) contact is open. This (transient) high induced voltage shock may damage the sensor or significantly reduce the service life of the sensor. Therefore, it is recommended to use a protection circuit with a clamping diode.

2. Prevent the valve from falling down from higher than 30cm to the hard surface, otherwise the working characteristics of its built-in sensor may deteriorate.

3. It is strictly prohibited to dismount remove the two way cartridge valve without permission, to change the valve parts without permission, or to remove or modify the throttle.

4. The position detector must be set by the valve manufacturer.

5. The hydraulic system shall prevent spool from shocking.

Tag: Cartridge Valve | Slip-in Cartridge Valve | 2-way Slip-in Cartridge Valve | Safety Cartridge Valve

English

English

Español

Español

Français

Français