Model: LCV

Description

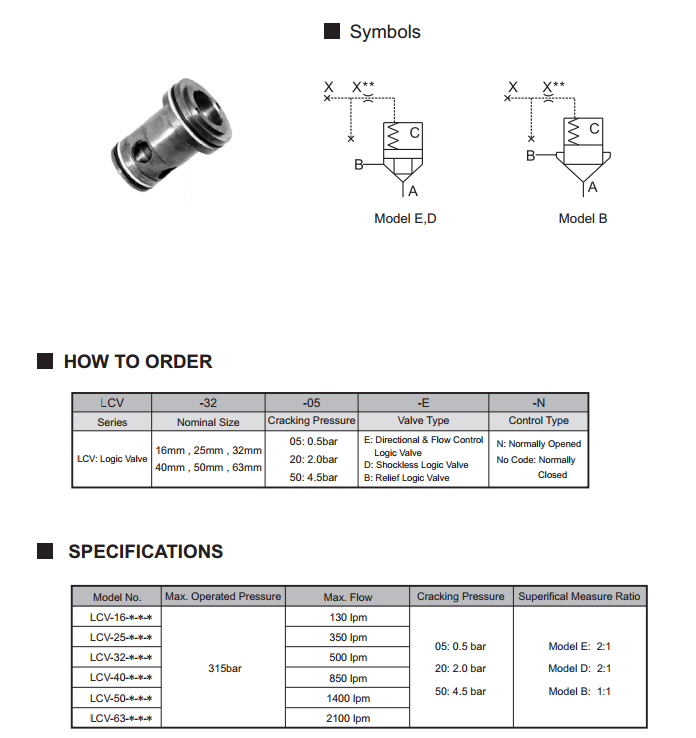

Poppet Valve, also known as cone valve, logic valve or mushroom valve, has two pipe connecting ports A and B and a control port C. The upper cavity is connected with the pilot control valve, communicating with the control oil circuit.

Working Principle

From the point of view of the working principle, it is equivalent to a hydraulic control one-way valve, when the control port C is connected with the oil tank, the poppet valve will be opened, the oil ports A and B will communicated with each other, so you can open or close the cone valve by using the pilot control valve to relieve or elevate pressure on the port C.

The logic valve can be combined with the small flow solenoid valve into a directional valve. It can be combined with various pilot pressure valves into various pressure control valves. If the B cavity is a return oil cavity, the valve will play the role of relief valve. If the B cavity is connected to a branch of the system, then the valve will play the role of the sequence valve.

Thus it can be seen that, a cone valve together with a solenoid valve and a pilot pressure valve plus taking measures to control speed can play the role of reversing valve, pressure valve and throttle valve in the system. Currently, this valve is usually used in the high-pressure, high-flow or super-high-flow hydraulic system.

Application

The mushroom valve is characterized by high pressure, high flow, fast response, compact structure and high integration, which is widely used in rolling mills, injection molding machines and machine tools, etc. The plug-in mounting parts are directly assembled within the ISO-standard valve bore, so as to avoid leakage, vibration and noise problems in piping.

Advantages

1. A control valve cover machined according to the ISO standard provides you with a multiple choice of control valves, which can be combined with the logic cartridge valve body into direction, flow or pressure control valve to meet demanded functions.

2. The machined bore diameter of the poppet valve body embedded in the oil circuit board is in line with the ISO 7368 (DIN 24342) standard.

3. The cone valve core is the one-way valve piston type design, so as to reduce the internal leakage to the lowest, and thus reduce the waste of energy. With low pressure drop and low calorific productivity, it can improve mechanical efficiency.

4. It responds nearly four times as fast as the slide valve so that the oil can immediately flow once the oil flow pushes away the piston. While the spool valve lags behind the flow of oil.

5. The logic valve body is placed in the oil circuit board, contributing to low noise, small vibration and stable mechanical operation. Its characteristics of multi-function simplify the demand for other types of valves. Also, it can prevent oil leakage caused by pipeline installation. It’s easy to install, and can lower the cost.

6. Small size and high flow. It’s recommended to use this series of products in the 100 l/min (25GPM) and above system. Applicable scope: large-scale machine tools, bending machines, die casting machines, plastic injection molding machines, etc.

7. Multi-direction, flow and pressure control valve is composed of plug-in mounting parts and covers with various control circuits

Note

You should choose an appropriate cone valve based on the required flow of the system.

1. For example, you can choose two-way cartridge valve if the flow is greater than or equal to 200l/min, and choose threaded cartridge logic valve if the flow is less than 20l/min.

2. The cartridge valve spool can be with a tail and with no tail, wherein, the one with a tail can play the role of buffer and throttle.

3. The spool can have various area ratios and the spring have various stiffness for you to choose, in order to achieve various opening pressures.

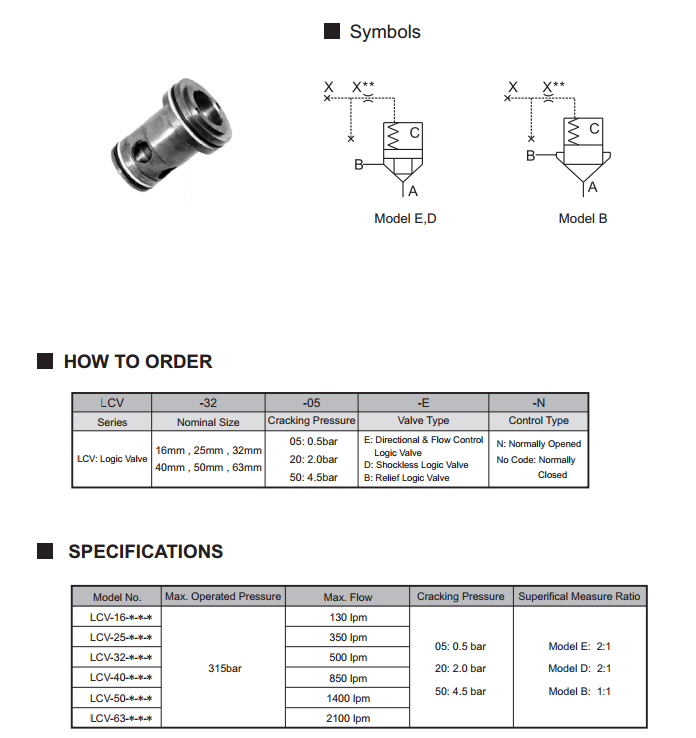

Parameters of Poppet Valve

Description

Poppet Valve, also known as cone valve, logic valve or mushroom valve, has two pipe connecting ports A and B and a control port C. The upper cavity is connected with the pilot control valve, communicating with the control oil circuit.

From the point of view of the working principle, it is equivalent to a hydraulic control one-way valve, when the control port C is connected with the oil tank, the poppet valve will be opened, the oil ports A and B will communicated with each other, so you can open or close the cone valve by using the pilot control valve to relieve or elevate pressure on the port C.

The logic valve can be combined with the small flow solenoid valve into a directional valve. It can be combined with various pilot pressure valves into various pressure control valves. If the B cavity is a return oil cavity, the valve will play the role of relief valve. If the B cavity is connected to a branch of the system, then the valve will play the role of the sequence valve.

Thus it can be seen that, a cone valve together with a solenoid valve and a pilot pressure valve plus taking measures to control speed can play the role of reversing valve, pressure valve and throttle valve in the system. Currently, this valve is usually used in the high-pressure, high-flow or super-high-flow hydraulic system.

The mushroom valve is characterized by high pressure, high flow, fast response, compact structure and high integration, which is widely used in rolling mills, injection molding machines and machine tools, etc. The plug-in mounting parts are directly assembled within the ISO-standard valve bore, so as to avoid leakage, vibration and noise problems in piping.

1. A control valve cover machined according to the ISO standard provides you with a multiple choice of control valves, which can be combined with the logic cartridge valve body into direction, flow or pressure control valve to meet demanded functions.

2. The machined bore diameter of the poppet valve body embedded in the oil circuit board is in line with the ISO 7368 (DIN 24342) standard.

3. The cone valve core is the one-way valve piston type design, so as to reduce the internal leakage to the lowest, and thus reduce the waste of energy. With low pressure drop and low calorific productivity, it can improve mechanical efficiency.

4. It responds nearly four times as fast as the slide valve so that the oil can immediately flow once the oil flow pushes away the piston. While the spool valve lags behind the flow of oil.

5. The logic valve body is placed in the oil circuit board, contributing to low noise, small vibration and stable mechanical operation. Its characteristics of multi-function simplify the demand for other types of valves. Also, it can prevent oil leakage caused by pipeline installation. It’s easy to install, and can lower the cost.

6. Small size and high flow. It’s recommended to use this series of products in the 100 l/min (25GPM) and above system. Applicable scope: large-scale machine tools, bending machines, die casting machines, plastic injection molding machines, etc.

7. Multi-direction, flow and pressure control valve is composed of plug-in mounting parts and covers with various control circuits

You should choose an appropriate cone valve based on the required flow of the system.

1. For example, you can choose two-way cartridge valve if the flow is greater than or equal to 200l/min, and choose threaded cartridge logic valve if the flow is less than 20l/min.

2. The cartridge valve spool can be with a tail and with no tail, wherein, the one with a tail can play the role of buffer and throttle.

3. The spool can have various area ratios and the spring have various stiffness for you to choose, in order to achieve various opening pressures.

English

English

Español

Español

Français

Français